What is Produced Water

Produced water is a type of water that proceeds to the surface as wastewater during oil and gas production.

The water characteristically consists of hydrocarbons from the deposit as well as naturally occurring toxic materials such as radium and arsenic, salts, and chemical extracts injected into the well to smooth extraction. These additives include cancer-causing agents and numerous other toxic substances that can harm human health and pollute the environment. The content and toxicity of produced water vary significantly, depending on the geology of the petroleum reservoir.

Produced water is the largest waste watercourse from fossil fuel extraction. Methods to extract fuels from elderly oilfields and alternative, or fracked, shale creations typically require far more water than conventional processes.

Oil and gas workers recycle some of their wastewater to extract more fuels but some processes need fresh water. Produced water is generated wherever gas and oil are extracted. Wastewater that isn’t reused is classically injected underground, hovering concerns for nearby landowners.

Management of Produced Water

Produced water management can be a troublesome task for a producer. Some estimates suggest water management is approximately 25% of the expense of a well in its lifetime. It regularly requires trucking through populated areas, employees, or contractors exposed to hazardous chemicals, and it generates public doubts.

Produced water recycling and reuse options have become more economical, accessible, and necessary. This is determined by four factors: the need to limit freshwater use, a more open political climate permitting reuse, the ban or over-capacity issues of removal by injection in some areas, and the advanced technologies available for both water treatment and possible reuse in accomplishments of fluid formulas.

Time-to-time assessment of produced water reuse choices is a valuable economic tool with sustainable resource benefits. It is important to recognize what reuse options are locally available, what are the requirements to meet the reuse, and what water quality exists in the field. These parameters are ever-changing, so the time-to-time evaluation of reuse feasibility is a smarter option than the permanent discharge of a reuse idea.

To begin a viability assessment, it is important to start with an accounting of the whole life cycle:. Such as resources used, processing of material, cost of transportation, human factors, and waste produced. And then start to develop any probable products that can be derived. Once a plan of possible reuse options is developed, the viability assessment can start.

Step to Evaluate the Feasibility of Produced water Reuse

Evaluate the Produced Water

Ensure that samples are collected at multiple periods in a well’s lifespan. The purpose is to have a strong idea of waste water patterns, both sequentially in a well’s lifetime and geographically in the field. Make sure the physical characteristics of water (density, temperature, etc.) are collected in addition to chemical configuration. Laboratory results are an important component of the success of a reuse/ recycling program.

Determine precise volume data from your wells. Compare several sources of where the volumes are informed. Occasionally, the volumes reported by the water transporter are not as precise as the measurements made by supervisory control and data acquisition tank readings. Comparison between both readings is essential. Repeat the procedure in the wells’ life span to develop predictive outlines as the wells age. Seasonal tendencies may also be deceptive after the data collection.

Evaluate the Options

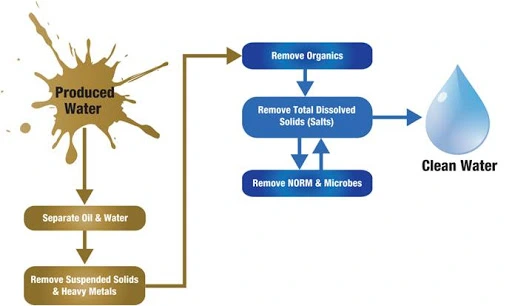

In the second step, review the results of water quality and regulate a list of reuse options, starting with a list of what can be reused with the lowest treatment: crop or golf course irrigation, evaporation beds, watering for pad recovery, dust control, livestock watering, and rangeland restoration.

If the water contaminants are present in higher concentrations, reuse options will need treatment before use. These typically have a more industrial application such as cooling tower water, paper and pulp mill water use, concrete and cement mixing, soluble-mineral extraction fluids, and mining flood fluids.

The production company will obtain the most financial benefit if there is a reuse application that can be used directly on-site, for example, hydraulic fracturing fluid components, drilling mud fluid additive, heavy brine for workovers, soil cement fluids for pad construction, enhanced oil recovery fluids in water stream or steam floods. The precise treatments required to reach functioning water quality will vary significantly but start with settling and filtration. The water chemistry will command what treatment is necessary.

While evaluating the reuse options, don’t contempt the physical characteristics of water. Produced water with an adequate density can be a feasible reuse of heavy brine water, once germ-free properly. Furthermore, produced water can come up-hole at temperatures near boiling point. This accessible energy can be used as heat during purification, steam production, field evaporation, and electricity generation.

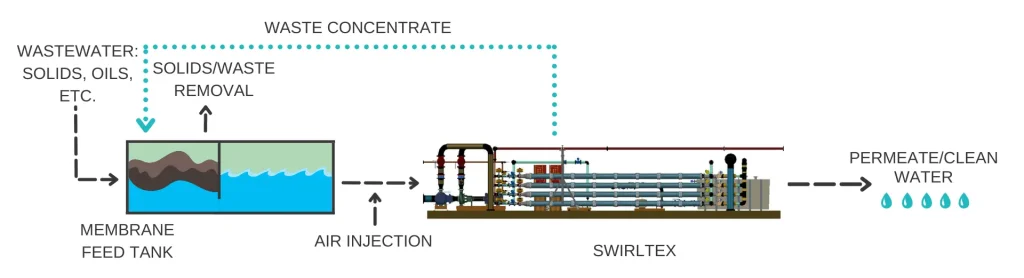

Evaluation of the physical inputs of the technology must needed for example, how will it be powered, will it function remotely, how many volumes can it handle, is it vigorous, will wells need to be shut down if something fails? Work through the large potentials of actual operation.

Evaluate the Costs to Treat Produced Water

Defining the costs for reuse is the third and most difficult part because the water volumes and chemistry will differ. It is hard to budget for the significant difference in nature. Start with the costs of freshwater tracing. Water supply charges are often a powerful factor in a reuse/recycling plan. Investigate the costs of the current disposal plan, for example, treatment, transport, and storage. Check with accountancy to see how the freshwater procuring and wastewater discarding fees are distributed amongst the lease and partners. Determine your company’s authentic cost.

Two methods to help comprise treatment costs are to manage the water quality in the field and to oversee the concentrations of the downhole chem used. After looking for the results of the chemical sampling program of the wells, manage your congregation system by leading the water to where there is one available cleaner source of produced water.

Instruct the collecting system or water transporters to load one of your storage facilities with less heavily polluted produced water to use as your source material for the reusable water. Also, manage the downhole paraffin oil thinners and scraping fluids of the well so that it is not foul the better-produced water collection. If sample results are remarkably high in methanol or other elements of your downhole chem, reduce the load or rate. The results are displaying it is just coming back up the hole unexpended.

Evaluate the Reality

After it has been confirmed that what wastewater reuse options are possible physically and reasonably, the feasibility determination isn’t over until the supervisory, social, and environmental impacts have been determined. Will the supervisors buy in? Is this going to require a year-long authorizing process? Does the treatment process use ignition to provide clean water?

Will the process itself need an additional air license? Will the limits of the air license be achievable? What other water, air, or waste problems will be generated? Are there quantifiable social impacts due to the recycling, noise, explosive atmospheres, traffic near neighborhoods, etc.? Luckily, as more reuse is put into place, expenses will begin to lower due to financial prudence of scale.

A documentary on waste water treatment can be watched from https://www.youtube.com/watch?v=MIgiQ3DKKKY

Conclusion

There are many more choices to make to improve the type of reuse possible for an operator such as disinfection, but this four-step process summarizes a good start to determine what process permits further scrutiny. Of course, the financial side is usually the basis of any reuse decision, but preparing a reuse feasibility study in advance of a freshwater deficit or a disposal issue will give the operator an benefit when it is essential to react to change.

The Climent Respect your roots, Protect your planet

The Climent Respect your roots, Protect your planet